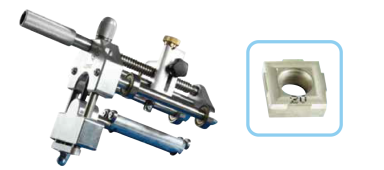

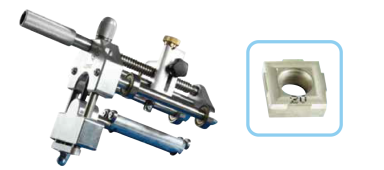

WELDER MACHINE

| Code | Size (mm) |

| FWM020032 | 20 - 32 |

| FWM020063 | 20 - 63 |

| FWM075110 | 75 - 110 |

| - | - |

| - | - |

| - | - |

| - | - |

| - | - |

| - | - |

WELDER MACHINE

| Code | Size (mm) |

| FWM020032 | 20 - 32 |

| FWM020063 | 20 - 63 |

| FWM075110 | 75 - 110 |

| - | - |

| - | - |

| - | - |

| - | - |

| - | - |

| - | - |

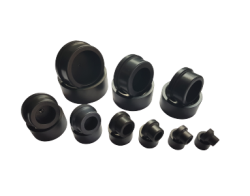

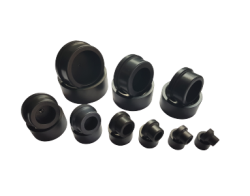

HEATING BUSHES

| Code | Size (mm) |

| FHB020 | 20 |

| FHB025 | 25 |

| FHB032 | 32 |

| FHB040 | 40 |

| FHB050 | 50 |

| FHB063 | 63 |

| FHB075 | 75 |

| FHB090 | 90 |

| FHB110 | 110 |

HEATING BUSHES

| Code | Size (mm) |

| FHB020 | 20 |

| FHB025 | 25 |

| FHB032 | 32 |

| FHB040 | 40 |

| FHB050 | 50 |

| FHB063 | 63 |

| FHB075 | 75 |

| FHB090 | 90 |

| FHB110 | 110 |

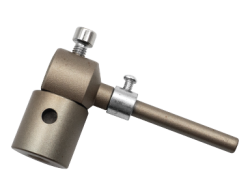

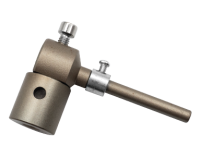

PE PEPAIRING ROD

| Code | Size (mm) |

| FRR007011 | 7 / 11 |

| - | - |

| - | - |

| - | - |

| - | - |

| - | - |

| - | - |

| - | - |

| - | - |

PE PEPAIRING ROD

| Code | Size (mm) |

| FRR007011 | 7 / 11 |

| - | - |

| - | - |

| - | - |

| - | - |

| - | - |

| - | - |

| - | - |

| - | - |

REPAIRING BUSHES

| Code | Size (mm) |

| FRB007 | 7 |

| FRB011 | 11 |

| - | - |

| - | - |

| - | - |

| - | - |

| - | - |

| - | - |

| - | - |

REPAIRING BUSHES

| Code | Size (mm) |

| FRB007 | 7 |

| FRB011 | 11 |

| - | - |

| - | - |

| - | - |

| - | - |

| - | - |

| - | - |

| - | - |

COLD RING

| Code | Size (mm) |

| FCR020032 | 20 - 32 |

| FCR040050 | 40 - 50 |

| FCR063075 | 63 - 75 |

| FCR090110 | 90 - 110 |

| - | - |

| - | - |

| - | - |

| - | - |

| - | - |

COLD RING

| Code | Size (mm) |

| FSR16020 | 20 - 32 |

| FSR16025 | 40 - 50 |

| FSR025 | 63 - 75 |

| FSR032 | 90 - 110 |

| - | - |

| - | - |

| - | - |

| - | - |

| - | - |

SINGLE-RING

| Code | Size (mm) |

| FSR16020 | PN16 - 20 |

| FSR16025 | PN16 - 25 |

| FSR025 | PN12.5 - 25 |

| FSR032 | PN12.5 - 32 |

| - | - |

| - | - |

| - | - |

| - | - |

| - | - |

SINGLE-RING

| Code | Size (mm) |

| FSR16020 | 20 - 32 |

| FSR16025 | 40 - 50 |

| FSR025 | 63 - 75 |

| FSR032 | 90 - 110 |

| - | - |

| - | - |

| - | - |

| - | - |

| - | - |

EASY CUTTER

| Code | Size (mm) |

| FPC020032 | 20 - 32 |

| - | - |

| - | - |

| - | - |

| - | - |

| - | - |

| - | - |

| - | - |

| - | - |

EASY CUTTER

| Code | Size (mm) |

| FPC020032 | 20 - 32 |

| - | - |

| - | - |

| - | - |

| - | - |

| - | - |

| - | - |

| - | - |

| - | - |

ORBIT

| Code | Size (mm) |

| FOB020063 | 20 - 63 |

| - | - |

| - | - |

| - | - |

| - | - |

| - | - |

| - | - |

| - | - |

| - | - |

ORBIT

| Code | Size (mm) |

| FOB020063 | 20 - 63 |

| - | - |

| - | - |

| - | - |

| - | - |

| - | - |

| - | - |

| - | - |

| - | - |

ROTARY PEELER

UNIPREPTM 4 / 1

4 Sided

Scraping Tip

| Features |

| • Uniprep 4 Pipe range : DN63 – DN250 |

| • Uniprep 1 Pipe Range : DN90 – DN400 |

| • One-Size-Fits-All |

| • Fastest and Cost Saving |

| • Easy, Even and Consistent |

| (peeling thickness at 0.1mm – 0.2mm per round) |

| • Replaceable & Rotatable 4-sided Peeling Tip |

| • Small Working Space, Large Clearance |

| • Uniprep 4 Peeling Length : 130mm |

| • Uniprep 1 Peeling Length : 150mm |

ROTARY PEELER

UNIPREPTM 4 / 1

4 Sided

Scraping Tip

| Features |

| • Uniprep 4 Pipe range : DN63 – DN250 |

| • Uniprep 1 Pipe Range : DN90 – DN400 |

| • One-Size-Fits-All |

| • Fastest and Cost Saving |

| • Easy, Even and Consistent |

| (peeling thickness at 0.1mm – 0.2mm per round) |

| • Replaceable & Rotatable 4-sided Peeling Tip |

| • Small Working Space, Large Clearance |

| • Uniprep 4 Peeling Length : 130mm |

| • Uniprep 1 Peeling Length : 150mm |

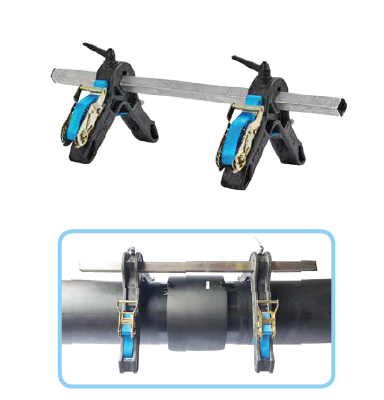

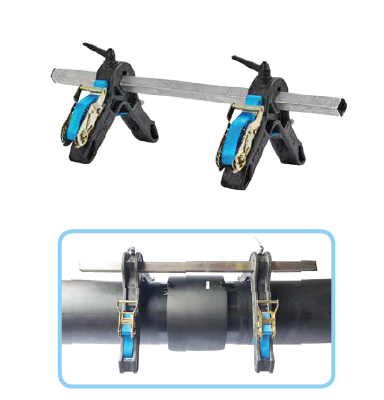

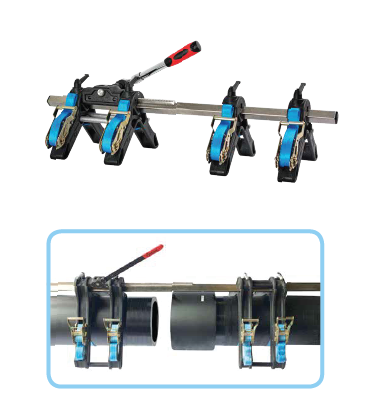

ELECTROFUSION ALIGNMENT CLAMP

STRAP CLAMP 200 / 500

| Features |

| • Strap Clamp 200 Pipe Range DN40 – DN200 |

| • Strap Clamp 500 Pipe Range DN160 – DN500 |

| • Compact, Quick to Install and Easy to Use |

| • Available in Single or Double Clamp Format (2 Clamps on each side) |

| • Angle making bar for 45o and 90o elbows available |

| • Lightest weight with strap holder |

| • Avoid Misalignment & Slip-off |

| • Robust and Firm Clamping |

Optional Angle Maker Knuckle

ELECTROFUSION ALIGNMENT CLAMP

STRAP CLAMP 200 / 500

| Features |

| • Strap Clamp 200 Pipe Range DN40 – DN200 |

| • Strap Clamp 500 Pipe Range DN160 – DN500 |

| • Compact, Quick to Install and Easy to Use |

| • Available in Single or Double Clamp Format (2 Clamps on each side) |

| • Angle making bar for 45o and 90o elbows available |

| • Lightest weight with strap holder |

| • Avoid Misalignment & Slip-off |

| • Robust and Firm Clamping |

Optional Angle Maker Knuckle

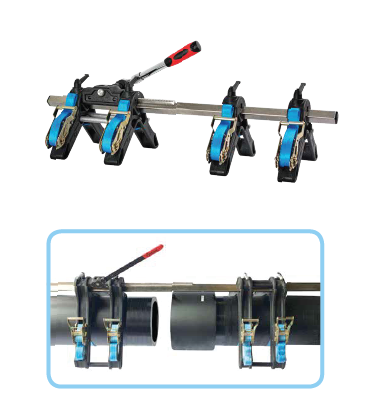

TITAN 200 / 500 PULL TOGETHER CLAMP

| Features |

| • Titan 200 Pipe Range DN40 – DN200 |

| • Titan 500 Pipe Range DN160 – DN500 |

| • Compact, Quick to Install and Easy to Use |

| • Available in Double Clamp Format (2 Clamps on each side) |

| • Capable of Pulling 12m length of Pipes using its rack and |

| pinion system |

| • Includes Pull Together Ratchet |

| • Avoid Misalignment & Slip-off |

| • Robust and Firm Clamping |

TITAN 200 / 500 PULL TOGETHER CLAMP

| Features |

| • Titan 200 Pipe Range DN40 – DN200 |

| • Titan 500 Pipe Range DN160 – DN500 |

| • Compact, Quick to Install and Easy to Use |

| • Available in Double Clamp Format (2 Clamps on each side) |

| • Capable of Pulling 12m length of Pipes using its rack and |

| pinion system |

| • Includes Pull Together Ratchet |

| • Avoid Misalignment & Slip-off |

| • Robust and Firm Clamping |

ELECTROFUSION WELDING WIPES

| Features |

| • Non-woven with Mesh Surface for effective cleaning |

| • Convenient Canister Pack - Use and Dispose |

| • Large Size 180mm x 230mm |

| • Cost Saving and No Wastage |

| • 70% Isopropyl / 30% Water |

| • 90% Isopropyl / 10% Water |

| • Best dirt and grease removing agent |

| - |

| - |

ELECTROFUSION WELDING WIPES

| Features |

| • Non-woven with Mesh Surface for effective cleaning |

| • Convenient Canister Pack - Use and Dispose |

| • Large Size 180mm x 230mm |

| • Cost Saving and No Wastage |

| • 70% Isopropyl / 30% Water |

| • 90% Isopropyl / 10% Water |

| • Best dirt and grease removing agent |

| - |

| - |

ACETONE

| Features |

| • Packed in 480ml and 1 litre bottles |

| • Quick drying after application |

| • 99% Acetone / 1% Water |

| • Effective dirt and grease removing agent |

| - |

| - |

ACETONE

| Features |

| • Packed in 480ml and 1 litre bottles |

| • Quick drying after application |

| • 99% Acetone / 1% Water |

| • Effective dirt and grease removing agent |

| - |

PRESS TOOL

Fully Open Position.

Wide opening jaws over the respecting Ring OD

1. 3-point Pivot Hinge Structure to produce high crimping force of 1 Tonne

2. Dual adjustment dials up to double-up tension adjustment

that prolongs the lifespan of tool

Our FY TOOL come with light-weight design, 3-point pivot hinge structure, dual dials for up to double-up tension adjustment and offer a crimping force of 1 tonne-force (tf) or 9,800 Newton (N). This translates to applying 25 kg-force by hand on tool will create a 1,000 kgforce on the crimped object. This tool has a conversion ratio of 1:40 or 40 times of the force gained.

FY TOOL comes in 4 individual sizes of DN20, DN25, DN32 and DN 40. Each tool weighs less than 2.5 kg.

• 1 Tonne of Crimping Force

• Longer tool life-span

• Lightweight and handy to use

• Complimentary tool package (terms & conditions applied)

| Code | Size |

| FYCT020 | 20 |

| FYCT025 | 25 |

| FYCT032 | 32 |

| FYCT040 | 40 |

| - | - |

| - | - |

PRESS TOOL

Our FY TOOL come with light-weight design, 3-point pivot hinge structure, dual dials for up to double-up tension adjustment and offer a crimping force of 1 tonne-force (tf) or 9,800 Newton (N). This translates to applying 25 kg-force by hand on tool will create a 1,000 kgforce on the crimped object. This tool has a conversion ratio of 1:40 or 40 times of the force gained.

FY TOOL comes in 4 individual sizes of DN20, DN25, DN32 and DN 40. Each tool weighs less than 2.5 kg.

• 1 Tonne of Crimping Force

• Longer tool life-span

• Lightweight and handy to use

• Complimentary tool package (terms & conditions applied)

Fully Open Position.

Wide opening jaws over the respecting Ring OD

1. 3-point Pivot Hinge Structure to produce high crimping force of 1 Tonne

2. Dual adjustment dials up to double-up tension adjustment

that prolongs the lifespan of tool

| Code | Size |

| FYCT020 | 20 |

| FYCT025 | 25 |

| FYCT032 | 32 |

| FYCT040 | 40 |

| - | - |

| - | - |